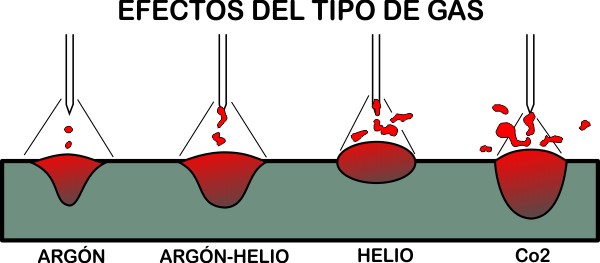

Composition: 100% Argon. Important: Pure argon is used for non-ferrous metals (magnesium, copper, nickel, and aluminum alloys).

This is a high-quality gas that ensures excellent protection and a stable arc at low current intensity. However, it may be insufficient for achieving deep penetration, high productivity, or good compactness in certain cases. At high intensities, the arc radiation in an argon atmosphere can cause ozone emissions, especially when welding pure aluminum.

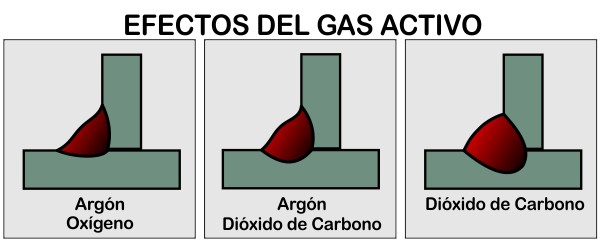

Composition: Argon with 2% Carbon Dioxide. This highly versatile mixture can be used with all arc types, especially for stainless steels, ensuring easy ignition and good arc stability. It is suitable for both single-pass and multi-pass welding. Additionally, its low CO2 content helps reduce fume emissions.

Composition: Argon with 3% Carbon Dioxide and 1% Oxygen. This mixture is specially designed for pulsed mode but is also suitable for non-pulsed mode on thin materials. Thanks to its low oxidation potential, it allows for minimal fume emissions while achieving high-quality surface welds. In pulsed mode, it stands out for its exceptional compactness.

Composition: Argon with 8% Carbon Dioxide. It is specifically designed for short-circuit and axial spray transfer modes and can also be used in pulsed mode. It enables welds with good penetration and low spatter and fume levels. When combined with low voltage settings and high wire speeds, ARCAL 21 allows for high welding speeds in automated or robotic applications.

Composition: Argon with 2% Oxygen. Ideal for welding carbon and low-alloy steels with thin to intermediate thicknesses. This mixture significantly improves arc stability, the surface tension of the molten pool (resulting in a flatter bead), as well as welding speed and penetration, with very low spatter levels. It is also suitable for welding austenitic stainless steels in short-circuit and spray transfer modes.

Composition: Argon with 5% Helium. As versatile as ARCAL 1, ARCAL 31 includes helium to reduce ozone emissions.

Composition: Argon with 20% Helium. Primarily intended for manual welding, this mixture offers:

Composition: Helium with 30% Argon. Recommended for automatic welding, it provides:

The deep penetration allows for better tolerance of the molten zone’s alignment, impeccable flat compactness, improved resistance to hot cracking, and cost savings on beveling.

Composition: Argon with 18% Helium and 1% Carbon Dioxide. This product improves weld appearance and productivity. The resulting beads are minimally oxidized, and thanks to the helium content, travel speed can increase by 10-15% while maintaining excellent wetting. ARCAL 121 is suitable for both single-pass and multi-pass welding and can be used with all arc modes. Its helium content significantly reduces harmful emissions.

Composition: Argon with 20% to 25% Carbon Dioxide. Its high CO2 content allows for good penetration and excellent compactness.

Also usable in MAG (FCAW) welding of stainless steels with flux-cored wires.

Also used with some flux-cored wires for FCAW welding of steels. However, due to the high emission of fumes and molten metal spatter when welding steels with solid wires, mixtures like argon with CO2 or even with O2, such as ATAL, ARCAL 21, and ARCAL 14, are preferred. These mixtures better stabilize the welding arc and reduce the emission of harmful effluents.

The proper balance of CO2 and O2 makes it a versatile mixture capable of achieving good welding speeds and fluidity. It is particularly suitable for solid wires, with a reduced level of spatter. Especially applicable for automated processes.

A versatile mixture usable in all arc modes, suitable for austenitic stainless steels (AISI 304, 316, etc.), both standard and low-carbon. Easy ignition and good arc stability, offering adequate penetration and welding speed. It can be applied for both single-pass and multi-pass welding.

What gas do you use? Leave us your comment...

They are already part of the Job Board

Relacionados: