In some regions, it’s called a plate roller, but that term is more commonly used for working with sheets or plates.

Special thanks to our friend Luis Mountaindew for contributing to the Herreros Argentinos group.

A finished project by our friend Mario Maldonado:

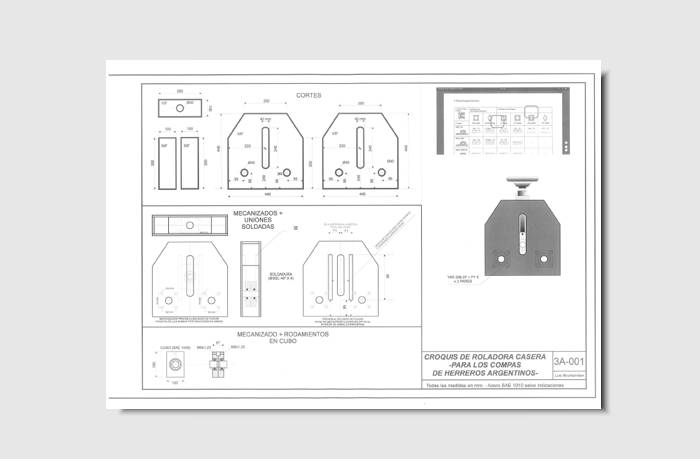

Download these PDF plans with measurements and specifications so you can build a bender. To curve pipes or solid square or round bars, you only need to replace the type of roller. The rest of the mechanism remains the same.

Download: CROQUIS_ROLADORA.pdf

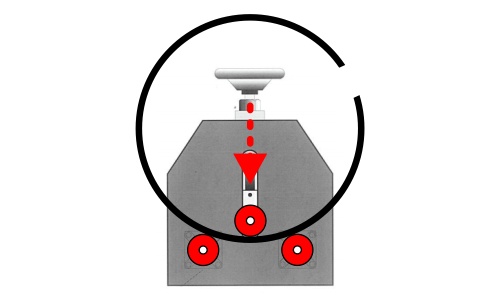

This mechanism is capable of producing a uniform curve, ideal for creating circles of various dimensions.

The two lower rollers are fixed in position, while the upper roller is the one that "works" by performing two tasks. One function of the central roller is to apply pressure to the piece to bend it. The other function is to rotate, transmitting this curve along the entire piece.

Often, the piece is passed through this machine multiple times, gradually increasing the curvature to avoid overloading both the roller bender and the piece.

They are already part of the Job Board