Previously, we analyzed what an angle grinder is used for and the benefits of a cordless grinder. This tool is extremely versatile, and even more so when paired with additional accessories. With such diverse uses, it’s logical that there’s a wide variety of discs available, which at first glance may look similar, causing confusion when purchasing this consumable.

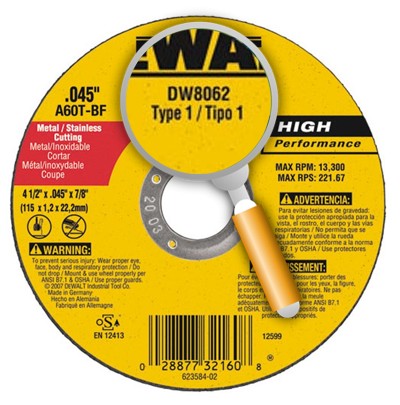

The diversity of standards from various countries and institutions applied to these discs doesn’t help clarify the situation, as manufacturers find themselves in a gray area where the application of these rules is initially left to each brand’s discretion. The main adopted standards are: ABNT NBR 15230, ANSI B7.1, EM 12413, and to bring some order to the matter, there’s O.S.A. (Organization for the Safety of Abrasives).

It’s important to clarify that this article exclusively covers abrasive discs. These work by friction, causing wear on the workpiece. Abrasive discs have a porous, granular, or rough surface to achieve the abrasion effect, unlike toothed discs that cut with their edge.

With the introduction complete, let’s start with the most basic classification:

The disc type is a classification from the Brazilian standard ABNT-NBR 15230, which organizes them by shape and function.

Most discs used in metalworking for cutting or grinding are made of granules or small abrasive stones bonded by an adhesive material. This material is usually phenolic resin, which can lose its adhesive properties over time, and after 3 years, it may not withstand the centrifugal force generated during use.

The support or structural material is also important. When plant-based fibers like cotton are used, they lose their properties over time. That’s why it’s important to respect the expiration date of these consumables.

These values are read as follows:

In some cases, the manufacturer specifies the rotation direction. Many discs work in only one direction, such as "flappers," which have many overlapping sanding flaps. Sometimes the manufacturer omits this information because it’s impossible to mount the disc incorrectly, as all grinders rotate in the same direction. But when the disc can be mounted either way...

The answer is simple: If the manufacturer doesn’t specify the rotation direction with an arrow, the disc can be mounted with the label facing inward or outward.

This can be specified in:

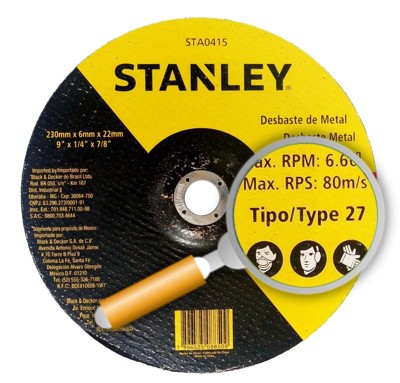

As a general rule for abrasive discs, the peripheral speed is 80m/s. RPM varies depending on the size; for example, smaller discs rotate faster to approach 80m/s at the contact surface. For this reason, it’s extremely dangerous to install a larger disc than specified for the grinder, as it would operate at a higher speed than it can handle, increasing the risk of breaking and injuring the operator.

By standard

discs rated for 80m/s

must have a

red band on their label.

It’s very important to consider the RPM of your grinder and only use discs within its operating range.

![]()

These graphics may indicate the working angle, personal protective equipment to use, and other warnings and recommendations.

![]()

We hope you found this information useful. If you liked the article... Share it!

They are already part of the Job Board