How to perfectly square a gate? How to check if it”s truly rectangular? If you’re a metalworker, you’ve probably looked at your squares with a bit of doubt, wondering if they’re really precise enough.

Because 90 degrees isn’t 89 or 91 — and when you install your work at the client’s place, any little twist will be noticeable sooner or later.

In this article, we’ll show you how to use simple Pythagorean tricks to get a perfect 90-degree square — all with just a tape measure and a marker.

Don’t worry, this won’t be a boring math lesson. You’ll see just how easy — and actually fun — this method can be.

First, let’s refresh some basic concepts we learned in school but might not remember so clearly anymore.

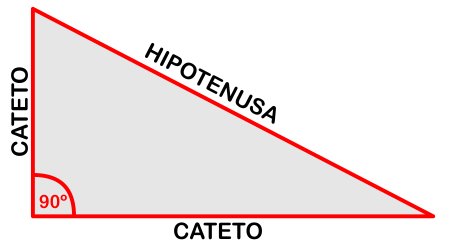

A right triangle is one that has a 90-degree angle.

The hypotenuse is the side opposite the 90º angle. The other two sides are called legs.

According to Pythagoras, the square of the hypotenuse is equal to the sum of the squares of the legs. This relationship between the sides of a right triangle always holds true, no exceptions.

Does that sound complicated? Don’t worry, it’s easier than it seems:

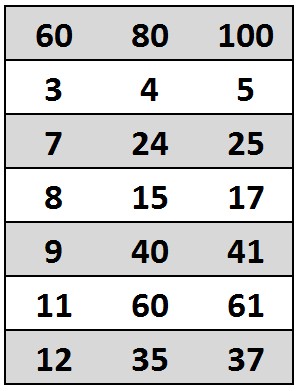

A Pythagorean triple consists of three numbers that satisfy the Pythagorean theorem and follow this format: LEG - LEG - HYPOTENUSE.

The most commonly used triple in metalworking is:

Remember, the last number in this measurement table for squaring — in this case, 100 — is our star, the hypotenuse. It will tell us if the pieces are aligned or if adjustments are needed. Here’s a table of commonly used Pythagorean triples:

You can use multiples or submultiples as long as you apply them to the entire triple. For example, instead of 3 - 4 - 5, you can use 30 - 40 - 50. The units of measurement don’t matter either — they can be millimeters, inches, centimeters, etc., as long as you use the same unit for all values.

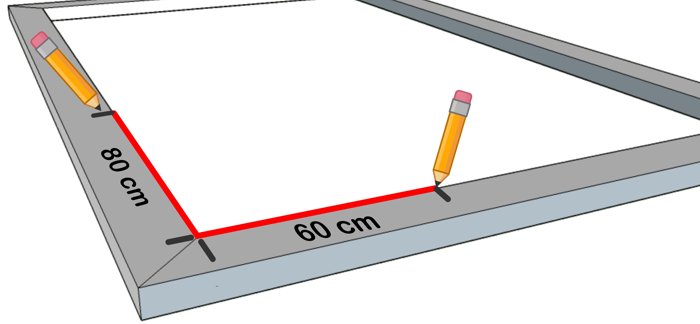

Now that we’ve covered this super-condensed introduction, let’s get to the practical part. Let’s say, for this example, that we’re building a sliding gate and starting with the perimeter frame of its structure.

Once the cuts are made and everything is ready to weld, we’ll check for square. Since this structure is quite large, we can’t rely on a magnetic square. In this case, we’ll use the 60 - 80 - 100 triple. Measure 60 centimeters from the corner along one side and 80 centimeters along the other side, marking the points to define the legs of our triangle.

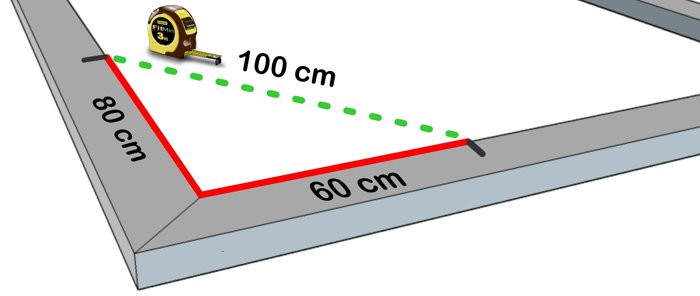

Now measure the hypotenuse. Using the tape measure, check the distance between the marks — it should be exactly 100 centimeters.

If the measurement doesn’t match the third number in the triple (100 in this case), adjust the pieces inward or outward as needed until the hypotenuse (the dotted green line) matches the value indicated in the Pythagorean triple table.

Once the measurement is correct, tighten the clamps and... time to weld!

For this procedure, you can take either the internal or external measurements of the pieces, but never both at the same time.

Next, we’ll look at another way to check alignment before welding.

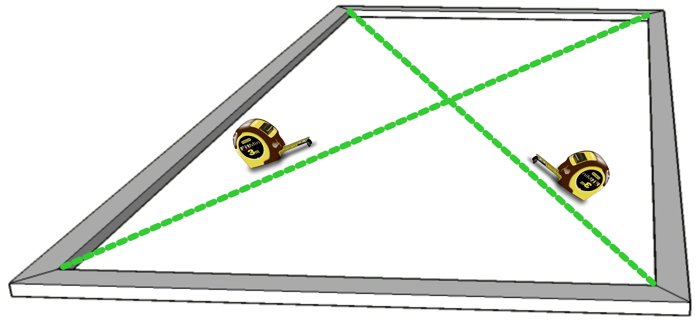

If you have all four sides cut, positioned, and tacked together for welding, you can measure the diagonals to ensure everything is properly squared.

Measure the distances between the opposite corners — both measurements should be equal.

If the values don’t match, you’ll need to carefully adjust one of the ends, measuring each time until the diagonals (marked in green in the diagram) are equal.

We hope you found this article helpful. Remember, your most important tool is your knowledge. By applying these methods, you can ensure your metalworking projects are perfectly squared, delivering quality and satisfaction to your clients.

They are already part of the Job Board