We were cautious and initially dismissed this news as one of those sensationalist internet stories designed to go viral. However, we kept an eye on the matter, albeit with little faith.

Eventually, we managed to contact the company supposedly building the bridge: MX3D from Amsterdam.

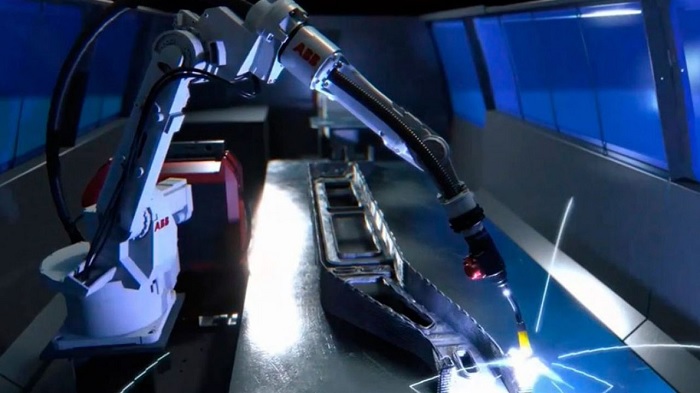

With over 10,000 kg of 3D-printed metal objects and more than 40 man-years of experience since 2014, MX3D is a pioneer in manufacturing using the WAAM (Wire Arc Additive Manufacturing) method, making metal 3D printing more flexible, faster, and cost-effective.

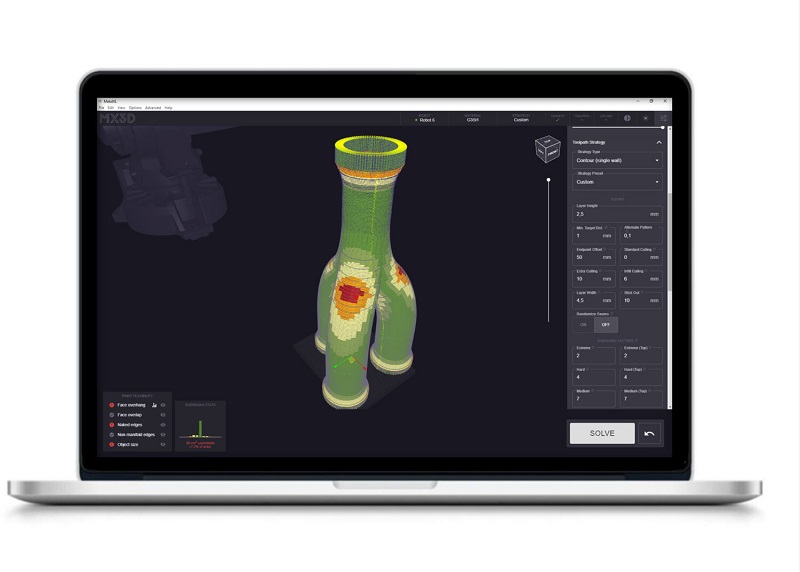

MX3D has revolutionized the market with the recent launch of the first dedicated robotic WAAM software, enabling companies, engineers, and designers to locally 3D print large-scale metal objects. Broadly speaking, the company provides industrial services, on-demand specific printing, software, and research.

To end the mystery: The bridge was real, and they were printing it.

This was the opportunity MX3D executives seized to showcase their services and demonstrate the company’s modern capabilities. They partnered with the Dutch government to fabricate and install the temporary bridge.

But in this article, we’re more interested in the manufacturing method. You can follow the bridge story here: The 3D-printed metal bridge is now installed

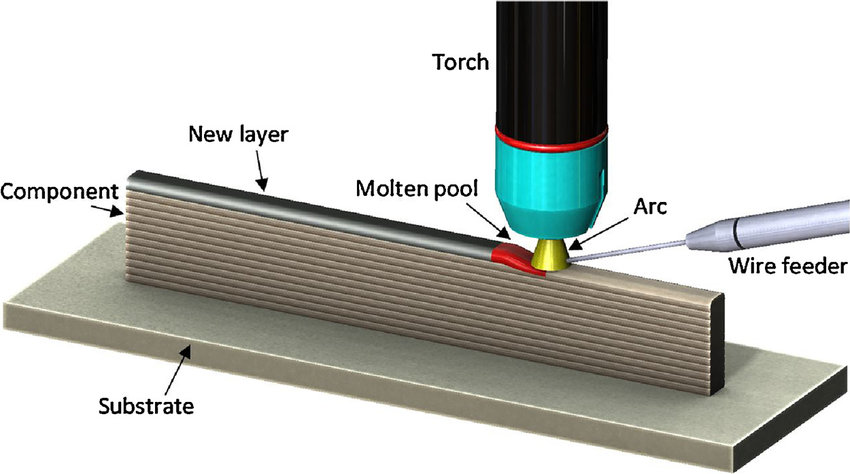

In broad terms, the process is very similar to MIG welding, where a gas-shielded arc melts the wire to deposit material. That’s where the term additive manufacturing comes from, as material is added layer by layer to form the piece.

Additive manufacturing processes create components almost from scratch by depositing layer upon layer of liquid or granular material onto a base plate. WAAM technology achieves this using a fusion welding electrode; the process is based on arc welding.

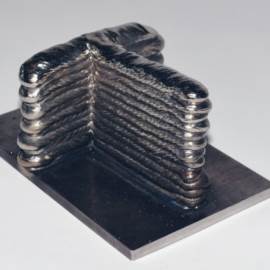

Generative manufacturing technologies are particularly useful for creating components with complex geometries. Additionally, the production time for parts is very short and cost-effective, making WAAM an attractive option for prototyping and small series production.

Compared to manufacturing a workpiece by milling a solid block, processing time, tool wear, and material waste are significantly lower.

Note:

Laser or electron beam

can also be used to melt the material.

In contrast to milling methods, 3D printing often results in rougher finishes with slightly irregular surfaces.

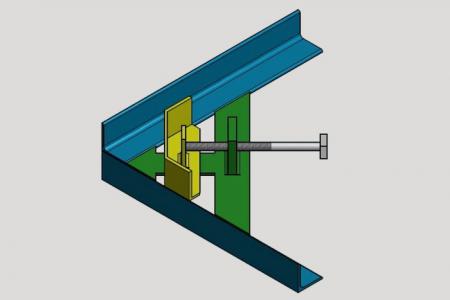

The challenge now is to move the torch to form the piece. Remember that CNC, or computer numerical control, is a system that allows the position of an element mounted on a machine tool to be controlled via a computer system.

In metal printing, two main options are used:

The latter is more commonly used due to its versatility and the significant advantage of being able to tilt the torch when the design requires angled applications.

Of course, the piece must first be designed on a computer. The system will use this design to determine the paths or "passes" that need to be made. This is converted into coordinates and ultimately into motor control.

Metal additive printing is a technology that’s here to stay. Before panicking, this won’t take anyone’s job away; on the contrary, the metal industry is extremely diverse, and having new technologies as an option for projects is always valuable.

Although it’s still restricted to specific fields, it’s just a matter of waiting a few years to see how far this innovative manufacturing method spreads.

They are already part of the Job Board

Relacionados: