The literal translation would be "anti-spatter," but in this case, it doesn’t prevent spatter. Instead, it protects surfaces from adhesion and the damage it can cause. The technical translation of ANTI-SPATTER in the welding field is NON-STICK.

A non-stick product is used to prevent the complex issues caused by welding spatter adhering to surfaces. Surprisingly, these projections can reach distances of up to 10 meters.

We can classify them into two main categories:

They can also be sub-classified based on their quality and chemical composition, but we won’t go into that much detail here.

Non-stick spray is more versatile as it can be used to protect both surfaces and the torch. However, it is more expensive and gets used up quickly, but it is very useful, especially when welding near painted or delicate parts.

Paste is used exclusively to protect the nozzle, which is the main topic of this article.

This paste, with its various chemical compositions depending on the manufacturer, always liquefies with heat, turning into an oily substance. The torch must be hot before dipping it into the paste, ensuring that the internal and external surfaces remain protected for a more or less prolonged period, depending on the product’s quality.

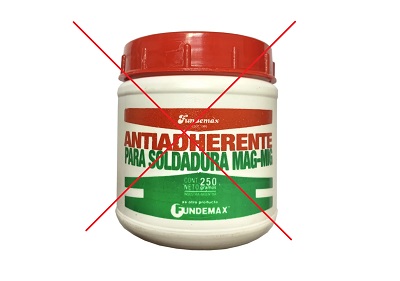

Avoid purchasing very cheap and low-quality products. Do not buy those in plastic containers, as they can melt and stick to the nozzle or puncture, causing product loss. Only buy those in metal cans.

Additionally, cheap pastes may emit toxic and foul-smelling gases and provide a short-lasting protective film.

The pastes with the best reviews among colleagues are:

Thank you for reading this far. If you enjoyed the content, feel free to share it. Cheers!

They are already part of the Job Board

Relacionados: