Experienced metalworkers know how to make the most of the magnetic square’s benefits, although many prefer to continue using the classic "C-clamp" and measure meticulously rather than trust this arrow-shaped magnet. However, it’s surprising how many workers only use this square for right angles, ignoring that it can also assist with joints in other positions.

After tacking the joint, you can remove the square once you’re sure there won’t be any deformations during the weld, to protect it from splatter.

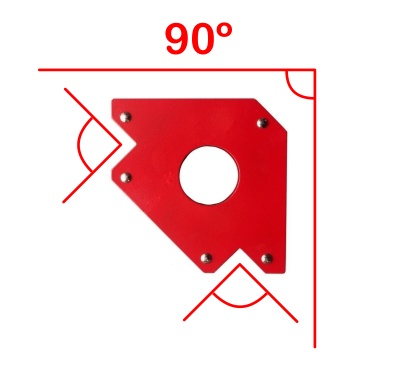

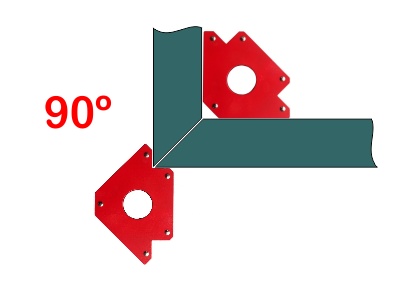

The arrow shape allows the square to be positioned at 90º inside or outside the structure, although the external placement has less contact surface, which affects the strength of the temporary joint as well as its accuracy.

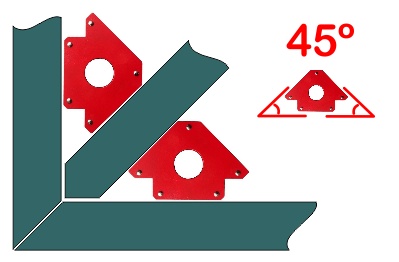

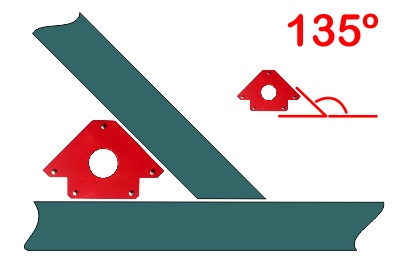

If we only needed right angles, this square would be square-shaped or L-shaped. Its design also allows us to divide this opening in half:

Supplementary Angle

= 180º - Xº

For example, the supplementary angle of 45º is 135º (180 - 45).

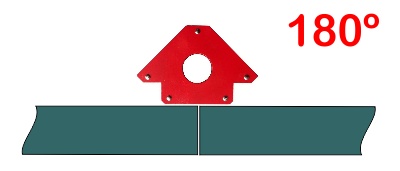

And the simplest position of all: The square can be used to align two pieces at 180º. In these cases, the accessory is very close to the weld, so it’s recommended to tack and remove it before continuing with the weld bead.

An option that allows for other alignments of the pieces to be welded is the irregular hexagon, which provides angles of 75º, 60º, and 30º in addition to the typical 90º and 45º.

If you need total freedom, there’s a wide variety of magnetic squares that allow you to adjust the angle to your liking.

Knowing your tools allows you to make the most of their functionalities and work better. If you found this article useful, share it and leave us your opinion.

They are already part of the Job Board